Roll Cutters

MMT’s FePeeler Roll Cutters set new standards in catheter production. Effortlessly achieve precise cuts on braided tubes, ensuring cleanliness, consistency, and quality at every stage of production.

MRC-1

This cutter uses a hand-held blade that fits into a .010″ wide slot for clean, straight cuts. The blade drops between ball bearings to cut the smallest sizes. It will cut parts from .020″ up to about .170″. It works great for braided catheter cuts, too.

MRC-XS

This cutter uses a hand-held blade that fits into a .010″ wide slot for clean, straight cuts. The blade drops between ball bearings to cut the smallest sizes and will cut parts down to .010″. It works great for braided catheter cuts, too.

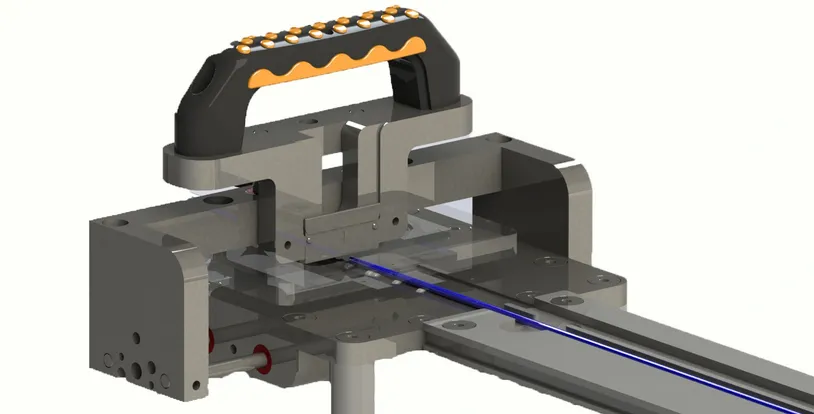

RC1

Roll cut parts from .050-.375 with or without braid. Our cutter was designed to give you straight cuts by extending the distance between blade supports, which minimizes blade angle movement. The cutting depth is adjustable with an ultra fine thread screw. Our cutter drives the rolling of your part on the OD rather than relying on the blade to make contact with the mandrel. This means less damage to your mandrels and less downforce to drive the cut. If you cut unbraided parts on a stainless mandrel, you will get many cuts on a single blade using the fine depth setting and 2-facet blades.

RC1-XL

The RC1-XL is the same great cutter, but it is designed for larger OD products requiring a longer stroke. With the larger rollers and long AccuTec blade, you can make a complete circumferential cut in one motion. It can cut up to .550″ OD products.

Recommended Blades

FEPeeler Braid-Blade

Our blade design is made from tungsten carbide and will outlast any other blade. No more one-cut-one-blade for your cut-to-length process. The blades are not sharp in the traditional sense, so no more injuries from blade handling. Stop throwing away 50-gallon drums of damaged razor blades with your one-blade-one-cut thinking. Contact us for price and availability.

Roll Cutting-RC1 & MRC

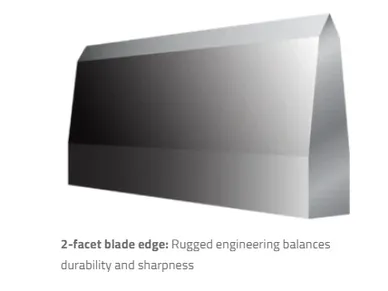

We recommend AccuTec #AGBL-7051 2-facet blades for roll cutting. The edge is much stronger, especially for cutting braided parts. Two-facet blades will give you a cleaner cut, especially on our roll cutters, because you will not be deforming them by rolling them on your mandrels. In the past, roll cutting has been one blade, one cut. With a careful depth setting, it is possible to trim parts with no braid on a metal mandrel with no blade damage.

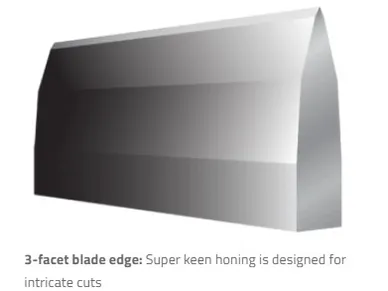

RC1-XL

RC1-XL was designed to use the AccuTec long blade (AGBL-7004). A standard blade is not long enough to make a complete circumferential cut. With this blade, you can easily roll-cut your largest parts. This long blade is only offered with 3-facet.

2-Facet Blade

2-Facet blades will hold up better when roll-cutting your braided parts. When you carefully set the cut depth on the cutter, you can actually see where the individual braids were cut on the blade.

3-Facet Blade

3-Facet blades are much better for precise cutting. Though they don’t hold up as well as a two-facet blade when roll cutting, you will have no problem cutting your catheters even with a heavy braid.

Pneumatic kit

Roll Cutter Pneumatic Kit

- Safely and reliably roll cut your braided or unbraided catheters to length.

- Anti-tie down two-hand actuator for safety

- Can be added to both RC1 and RC1-XL roll cutters

- Pneumatic only, no electricity access needed

- The pneumatic timer ensures the blade is lowered before moving